The story

Mobirolo: a story of passion The dream "to create stairs of quality and comfort" of the founder , begins in 1966, in an artisanal laboratory of Reggio Emilia , a small town in the north of Italy . Since that moment the technological experimentation, a hard dedication, a meticulous attention for details , the innovation and the constant aesthetical research will be always the guidelines of the Mobirolo’s history. Thanks to them , Mobirolo is now considered one of the leading companies for the production of stairs of high quality and aesthetic level .

1970: together with the production of retractable stairs, Mobirolo begins to look at new technological and stylistic solutions. The line "Spiral" is presented in the market : a selection of spiral staircases conceived to harmonize functionality and aesthetics in vertical sense .

1980: Following the change of cultural moods and the trends in the arts , architecture and interior design , Mobirolo introduces the line "OPEN": a contemporary re-interpretation of the traditional wooden stairs, to transforms the classical identity of the product in a piece of furniture for the contemporary living space.

1990: New graphic lines and some industrial materials will typify the line " Modular " : the highest expression of industrial and architectural design : by the experimentation and the application of new materials for the structures , such as aluminium and transparent polycarbonate Mobirolo creates a new vertical design.

XXI Century: It’s the last "Tech" line, that interprets the new contemporary world , and the cultural contamination of styles, shapes and materials. An eclectic mix of essential industrial design and LED technology, aerial transparency of the stratified glass married with chrome steel banisters , graphic shapes and laser-cutting structures combined to the warm and truthfulness colours of wood ... everything becomes a style and everything is in motion.

Mission: We work to satisfy the expectations of our customers , to grant an excellent quality of the product and the service.

Our values:

Reliability and commitment: we work to deliver a product of quality, created and tailored according the needs of the customer . A product made to last.

Quality of the product and the service: we work to ensure an excellent quality. We constantly execute a careful control of materials and the finishing to satisfy our customers. We are committed to comply the terms of delivery by a continuous inspection of the production planning. We guarantee the best technical and commercial advices, in order to find the best solution for our customer ,according to its needs. Every day we are engaged to improve the quality of the product, of the service and of the procedures , by a constant activity of research, staff training and the update of the technologies we work with .

Ethical Commitment and Responsibility: we are engaged to encourage the development of work and organization, for a model of business ethically correct, respectful of the environment and the human dignity.

We work with seriousness and rigor by respecting the laws, the people and the planet we live on, in order to ensure a good present and a better future to all the next generations.

We are committed to improve the quality of life thanks to an environmental and sustainable production, by optimizing the energy resources we use ; we select raw materials strictly controlled, with low impact on the environment and harmless to the health. We directly differentiate the wastes for a proper management of recycling .

Made in Italy

For Mobirolo " Made in Italy " means passion for our work, to produce concretely in our plants in Italy; It means to preserve the craftsmanship know-how of our region , providing a meticulous attention to the details; For Mobirolo " Made in Italy " means a continuous experimentation of new technologies and different processes to improve our Italian quality.

Design

For Mobirolo "Made in Italy" means to conceive the design as a project in constant evolution: a source of ideas, styles and lines which take shape to become furnishing of strong personality ; a synthesis of harmony and contrast, utility and beauty, functionality and aesthetics, past and future. To create and to make objects for living along the time.

Environment

Mobirolo has always paid great attention to the environment and its safeguard and this attitude is one of the values of our Company.

The recycle of materials as ethical commitment and resource: the wood residues are recuperated and mainly used for the heating system of the production sites; the residues of remaining parts are sent to specialized companies from which they derive other objects or materials.

Mobirolo company has installed a photovoltaic system with solar panels which provides a partial energy independence and a significant reduction of potential harmful emissions in the air .

We deeply believe in FSC 100% (License Code FSC-C108913). Certification and we guarantee that, the beech wood used for our products, comes from forests "responsibly" managed and controlled, respecting the environment, the natural resources and the people.

Our wood products are painted and treated by "water varnishes " , that dramatically reduces the emission of chemical agents in the atmosphere , granting harmless effects for health.

Finally, the production in our Italian plants, together with a short supply chain thanks to the cooperation with local suppliers, let us contribute to reduce the negative pollution effects due to long distance transportations for manufacturing operations.

Materials

Beech wood

Hardwood laminated panel in staves and stuck together.

We only use wood with FSC 100% (License Code FSC-C108913). This certification ensures that the wood used for manufactures completely comes from forests managed and controlled according rigorous regulations against a wild deforestation, to safeguard the environment .

Bonding: In accordance with EN 204-D3 law

Formaldehyde emissions: in conformity to class E1, according to EN 717-2/94 law

Fir Wood

Laminated Panel in entire stave , coming from controlled cultivations exclusively.

Gluing: vinyl glue D3 (DIN EN 204) in conformity to the European regulations in force .

The wood is dried by natural process and it is not treated with components potentially harmful to the environment or to humans.

Glass

The glass used for our treads and railings’ panels is tempered and laminated (2 or 3 layers of tempered glass, and layers of EVA - Ethyl Vinyl Acetate applied inside )

Steel

We use construction steels of different kind and that are protected by hot-dip galvanizing (suitable for outdoor use) or with coating to grant duration along the time .

The painting can be suitable for indoor or outdoor use ; for outdoor uses hot-dip galvanizing treatment is recommended as thermosetting powder painting is less durable and suitable for marine or medium pollution environments.

Stainless Steel

Stainless steel AISI 304 and AISI 316 with glazing treatment 320, highly resistant to corrosion and the atmospheric agents.

The main difference between the stainless steel AISI 304 and AISI 316 is in their different chemical composition: the AISI 316 steel contains molybdenum, which makes it more resistant to corrosion ; this element makes steel more suitable in areas and marine environments, in areas of high air pollution or in the presence of acid rains.

The presence of rust spots on the stainless steel does not imply the quality level of the product , but its chemical reaction depending on the area of ??installation such as marine environments or areas with high air pollution

These possible reactions of the material to the external factors , can be solved by regular and periodic care maintenance, highly recommended.

The possible presence of points of rust along the time absolutely does not damage the structure of the material, and it’s only a matter of aesthetics.

This occurrence shall not be considered a defect of the product or its components and the product warranty will not cover it . Any claim on this matter will be accepted.

Aluminium

T6060 T5 aluminium, painted as metal or anodising.

Zamak

ZAMAK it’s a zinc alloy, combined with small percentages of aluminium, magnesium and copper, worked with die casting moulding procedure.

Plastic materials

Plastics components, injection and extruded moulded, constituted by thermoplastic polymers of various materials such as: ABS (Acrylonitrile butadiene styrene), PMMA (Poly methyl methacrylate), PP (Polypropylene), PC (Polycarbonate), PA (Polyamide), PVC (Polyvinyl chloride) and so forth.

PLEXIGLAS

The Plexiglas or PMMA (Poly methyl methacrylate) is a thermoplastic material, from quality glass-like, stiff, hard. It is usually very transparent, more than the glass, with UV rays stability and good resistance to weathering and chemical agents.

It has an high resistance to abrasion and it’s also highly resistant to aging, even if exposed to the sun.

Water based ecological varnishing for wood

The wood is treated with special substances, for protective and decorative scopes.

The coating cycle is constituted by a series of operations:

• The sanding, to make the surface smooth and porous.

• The painting, to modify, enhance or uniform the colour.

• The isolation, to favour a better adherence of varnishing products.

• The filling, to take over the pores up to the extent desired.

• The finish, to apply the final layer of varnish and obtain the desired aesthetic effect.

Electrostatic metal coating with thermosetting powders

This type of coating is very durable thanks to a remarkable adherence to surfaces, obtained by the polymerization of the powders at high temperatures in a static oven.

The painting process is based on the creation of an electrostatic field at high voltage, through which the part to be coated is positively charged: an air flow directs the dust particles negatively charged towards the surface of the product, on which they settle for effect of the attraction by the positive electrostatic field.

The painted elements are put in a furnace, with a temperature of about 180° C.

The heating starts a phenomenon of melting and cross-linking of the powders which produces finally a layer of paint, homogeneous in its thickness and degree of adherence.

Hot-dip galvanizing

Treatment used for the protection of ferrous steels against corrosion by atmospheric agents.

This treatment is most suitable for a long lasting in outdoor environments.

With “hot-dip galvanizing” is intended the immersion of the steel element to be protected in a bath of molten zinc at a temperature of about 455 ° C.

Thanks to the pre-treatment in a bath of liquefied salts (zinc chloride and ammonium chloride), the steel gets alloyed with the zinc: this process confers a resistance to corrosion highly superior rather than in the electrolytic galvanizing.

This surface treatment, high-performance under the protective aspect, is nevertheless available only available in the colour typical of zinc; it also leaves a nicely irregular surface and, in some case, could be little pouring signs.

Maintenance and cleaning:

The stainless steel AISI304 or AISI316 is a material invulnerable by the atmospheric agents, but it needs a regular cleaning .

It will be important to clean these surfaces with the same frequency with which are cleaned windows and glass walls.

More specifically:

With AISI304 and satin finish:

- Cleaning every 3-4 months, depending by the local atmospheric conditions

- AISI304 is not recommended for the marine environment

AISI316 with satin finish:

- Cleaning every 1-2 months

- In applications where AISI316, AISI304 or Painted Steel Fe 360 ??B are mounted in interiors, it will be sufficient the common cleaning from dust.

For wooden elements it will be important to clean the surfaces with the same frequency with which are cleaned windows and glass walls.

Cleaning products:

Stainless steel and painted steel:

Normally , it is sufficient to wash the elements with soap and water, thoroughly rinse and wipe dry with a cloth to keep the shiny appearance (everything must be dried thoroughly, to avoid stains caused by the hardness of the water).

The cleaning with specific products degreasing, acid-free and non-abrasive normally available on market is recommended at least once a year for the outdoor use and about every two years in interiors.

These products should be used also in the uncommon case of appearing of little rust dots.

Wood:

It is suggested to clean at least once a year with products normally available on the market, better if specifically conceived for wood. We suggest non-acidic, non-abrasive and non-alkaline products.

Plexiglas:

Whenever necessary, a wash with neutral detergents will be sufficient to restore the gloss to this material.

The scratch resistance of the Plexiglas is the same of the wood, but can it be buffed .

Over time the time, this material might dull: using a product like liquid wax "Polish" for automotive bodywork the Plexiglas can return at its original brilliance and transparency.

Certification and conformity

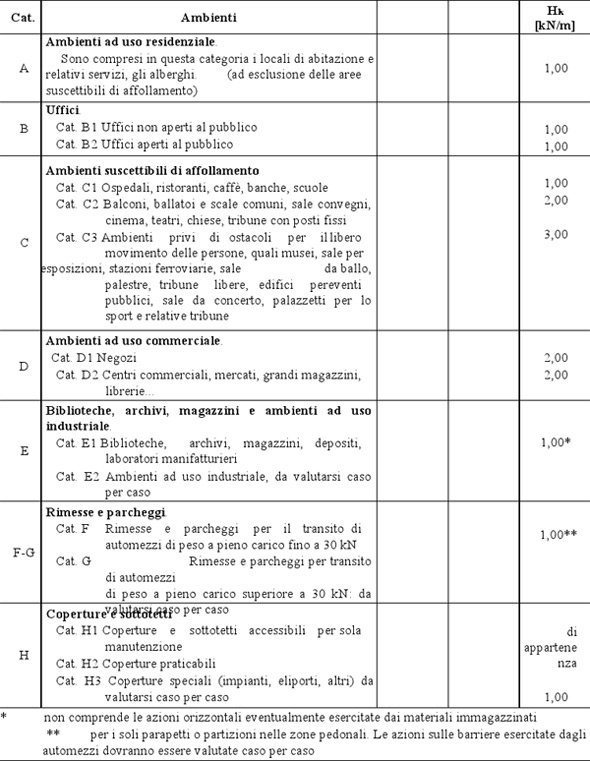

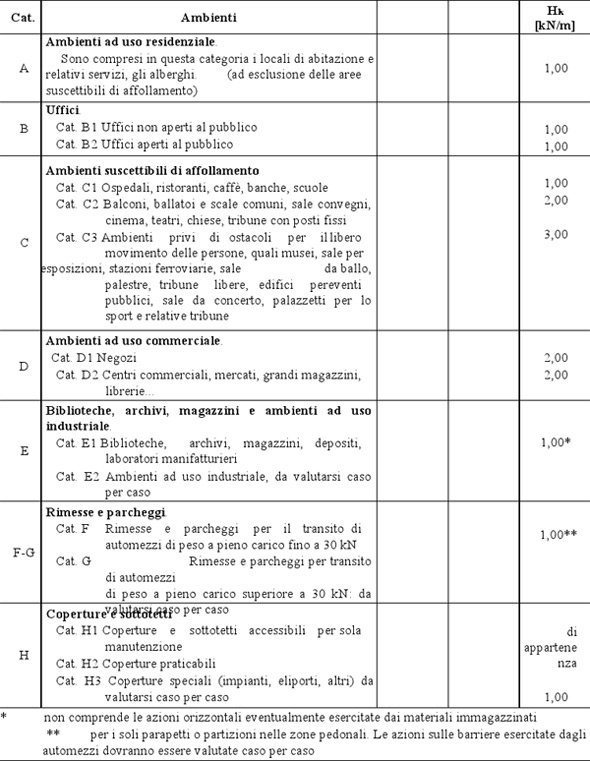

Stair railings, balustrade for concrete stairs and banisters Carrying capacity 1,00 KN/linear meter, as by Italian law (D.M. 14 january 2008)

• UNI 10806 norm

• UNI 10807 norm

• UNI 10808 norm (Chrome excluded, included Chrome on Esperia).

Certifications on products:

• FSC 100% (License Code FSC-C108913) for all the beech products

• In compliance with the norm UNI EN 14975 norm for retractable stairs ZX, D and Zenith.

• Certified Quality System ISO 9001:2008

Services

Free counseling and quick execution of project: supported by our designers and our local retailer net we can easily create the right staircase solution for all the spaces and interiors

After sale assistance with a net of qualified installers, who will give their professional assistance for the fitting

Shipment and delivery : Thanks to our qualified carriers , you can count on a punctual delivery door to door

Quality warranty: all our products are covered by a product guarantee

General sales conditions

1) Pursuant to the supply contract, the supply request for Mobirolo products must be submitted through an order, which needs to be delivered by mail by means of the dedicated forms drafted by Mobirolo or via email.. Paper or electronic orders need to be drafted fully and comprehensibly and must be signed by the Dealer wherever requested. The prices of the products requested are reported in the price list valid when the order is received by Mobirolo. Mobirolo reserves the right to consider incomplete, unreadable and/or partially signed orders as invalid.

2) The Dealer shall inform Mobirolo about laws and regulations with which the products need to comply and is solely responsible for the data of the staircase supplied according to the mail and/or email orders transmitted to Mobirolo and is responsible for the compliance of staircases with the laws in force in the destination country. Mobirolo reserves the right to modify the specifications included in the orders if they are incompatible with the product requested and/or overtly incorrect. In such cases Mobirolo shall request the Dealer’s approval of the changes and, after they have been accepted, the Dealer shall be considered solely responsible for such changes. In the light of the difficulties they cause, staircases not parallel nor perpendicular to the walls shall not lead to Mobirolo's objective liability if different angles obtain between the staircases and perimeter walls.

3) Mobirolo reserves the right to reject orders within 30 days after they have been received. The orders may not be revoked by Dealers and they shall be considered explicitly implemented and accepted for the product model or models which are being manufactured when the order is executed even if they are different from those reported in the catalogues and the samples provided before the order date. If changes are needed, the orders shall be returned to the Dealer to be explicitly confirmed within the deadline reported above. The orders shall also include the detailed description of: any changes of the data submitted by the Dealer, terms of delivery, place of destination, size/description of the staircases, staircase layout plan, etc. Within 10 days after having received the acknowledgement of order described above, the Dealer shall return the acknowledgement of order itself duly signed. The delivery date shall be calculated starting from the date when the order duly signed is returned.

4) The colour shades of Mobirolo products are not classified according to the RAL scale since they derive from natural wood colour shades and may vary according to each wood lot. The Dealer explicitly accepts any natural colour shade changes of the products supplied as compared to samples, as well as colour differences among parts; therefore, no compensation or indemnity may be requested by the Dealer from Mobirolo.

5) The terms of delivery shall be considered indicative and are applied starting from the actual date when Mobirolo starts manufacturing the products concerned. In case of orders calling for the Dealer’s confirmation of the project, the terms of delivery shall be enforced starting from the date when the order is actually confirmed by the Dealer. Delayed deliveries due to production or transport problems which are made within thirty days after the indicative delivery date envisaged in the acknowledgement of order shall not entitle the Dealer to request any compensation or indemnity. In the case of longer delays due to force majeure, unforeseeable circumstances or facts and circumstances beyond Mobirolo's control, no damage compensation may be requested by the Dealer from Mobirolo.

6) The supply is delivered according to the CPT convention (INCOTERMS 2010); the presence of apparent and obvious damage or the lack of parcels must be immediately reported in detail by the Dealer in the transport document. Generic reservations shall not be accepted for the purpose of insuring the products. Transport costs are those envisaged in the specific price lists valid when goods are delivered and refer to deliveries in the territory of the State specified therein excluding islands and overseas dominions. Mobirolo reserves the right to notify different transport costs for the latter destinations.

7) The Dealer takes on the responsibility in terms of the consequences of the storage of delivered goods if they are not installed immediately but after a certain period of time.

8) The payment of the goods supplied shall take place in advance before the goods are collected, although Mobirolo is entitled to request a deposit when orders are confirmed of staircases manufactured according to specific sizes provided by the Dealer. Payment delays can be agreed between Mobirolo and the Dealer.

9) The Dealer may not reject or postpone the delivery of the goods being supplied with reference to the indicative delivery date envisaged in the acknowledgement of order. Therefore, the costs deriving from the failed delivery or storage of the goods - for which the Carrier is not responsible - shall be incurred by the Dealer.

10) The goods supplied by Mobirolo are guaranteed against manufacturing defects and faults for two years after the date of delivery. Any defects and faults of the goods supplied shall be notified to Mobirolo within 8 days after their delivery or when hidden defects or faults are detected. The warranty covers the defective component only; consequently, disassembling/assembling and transport costs are excluded and shall be incurred by the Dealer.

11) The Dealer is solely responsible for the installation of the products supplied and shall incur all costs. Therefore, Mobirolo shall not be considered responsible for faults, defects and/or any problem which may emerge affecting both the products supplied and the wall structures and the Dealer’s property in general following the installation of the goods.

12) The Dealer acknowledges that Mobirolo is the sole holder and owner of the rights connected to the brands, MOBICAD software and/or other software – whatever its name – owned by Mobirolo, as well as the know-how relating to product design. Upon completion of the assembling and installation operations, the Dealer undertakes to apply the Mobirolo trademarks onto the products supplied. The Dealer undertakes to restrain from patenting the products supplied or registering the Mobirolo trademarks and undertakes to acknowledge the property right of Mobirolo on the “mobirolo.it”, “mobirolo.com” and similar Internet domains; the Dealer undertakes to restrain from registering Internet domains in its own name, regardless of their wording, including the name Mobirolo and/or names of Mobirolo products and trademarks. Mobirolo supplies the MOBICAD software, which may be installed exclusively on the Dealer’s computers. The MOBICAD Software may not be copied or reproduced, albeit partially, decompiled, disassembled, subject to reverse engineering or any other operation aimed at extracting, copying or reproducing source files or any other part of the software. No warranty is provided on the correct operation of MOBICAD or the correctness of the data it contains.

13) The present agreement is governed by the Italian law.